Combustion engine development is still important and the drive for efficiency will continue for as long as engines remain in use and the new Nissan e-Power system is a case in point.

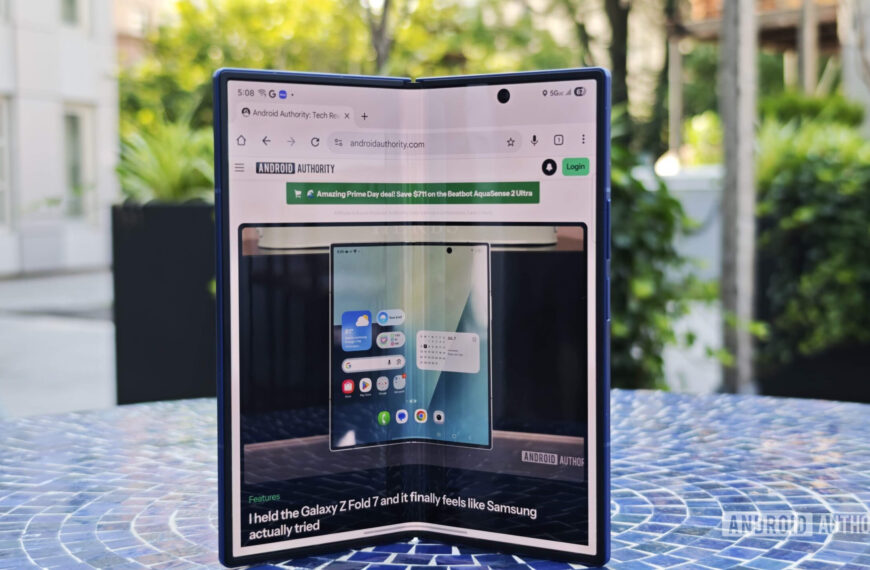

The first vehicle to use the latest, third-generation e-Power system, initially introduced in 2016, is the Qashqai, which began production in the UK in last year.

Nissan’s e-Power powertrain is a series hybrid system, so the 1.5-litre petrol engine works as a generator to charge the battery rather than driving the wheels. Because of that, the engine doesn’t need to produce transient bursts of power and torque for acceleration.

It drives an integral generator to charge the battery, but when driving at high speeds, it can also feed power via the inverter (power electronics) directly to the main drive motor while charging the battery at the same time.

An advantage of this approach is that it overcomes one of the combustion engine’s main drawbacks: relatively poor thermal efficiency. Combustion engines produce power by burning fuel, which releases expanding gases to drive pistons and produce mechanical power.

But only some of the energy in the fuel is converted into mechanical energy and the rest is wasted as heat. In older engines, thermal efficiency could be as low as 20-30%, although today some are exceeding 30% and heading to 40%.

Nissan says the new e-Power engine can achieve 42% partly because the engine is designed specifically as a generator and not hampered by the need to cope with transient demands like a conventional drivetrain, and also thanks to a complex combustion strategy called STARC (Strong Tumble and Appropriately Robust ignition Channel concept).

As the name suggests, it’s all about creating a strong tumble effect when air rushes into the cylinders plus ignition strategies to burn the fuel-air mixture as efficiently as possible.

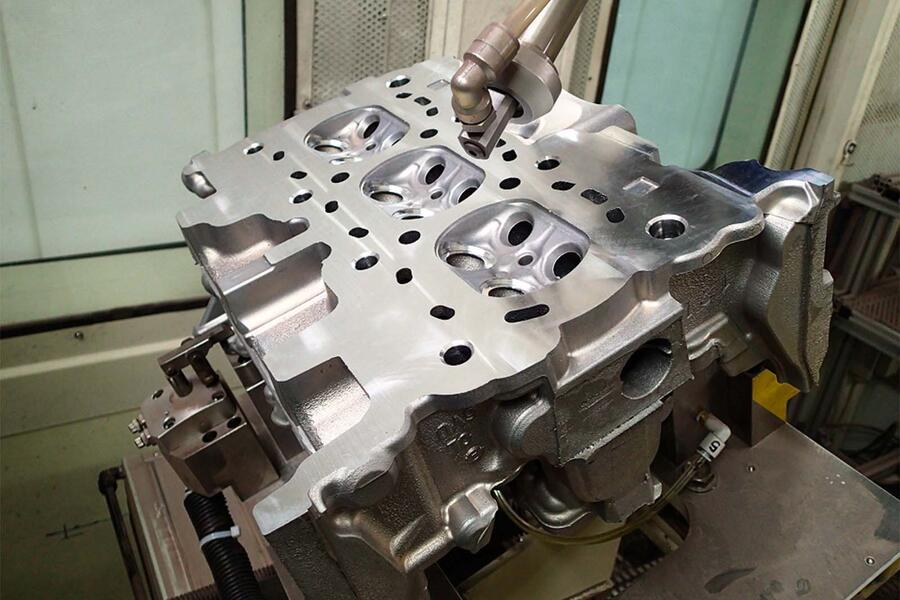

A new process called cold spray technology has helped achieve that by doing away with traditional valve seat inserts in the cylinder head, the rings of hardened metal pressed into the alloy cylinder head on which the valves sit as they close.

Their presence leads to a compromise in the aerodynamics of the inlet tract but the new method literally sprays hardened material onto the cylinder head valve seat areas instead, allowing more flexibility in designing the shape of valve opening.

This innovation – along with an unusually large turbo to reduce pumping losses plus timing strategies to allow a high compression ratio of 13:1- is said to balance high thermal efficiency with high power.